What are the key differences in efficiency, handling, and environmental impact between using raw paddy straw and paddy straw pellets in a boiler?

Using paddy straw directly in a boiler and using paddy straw pellets in a boiler present different challenges and advantages. Here are the key points comparing the two: Challenges of Using Paddy Straw Directly in Boilers: Advantages of Using Paddy Straw Pellets in Boilers:

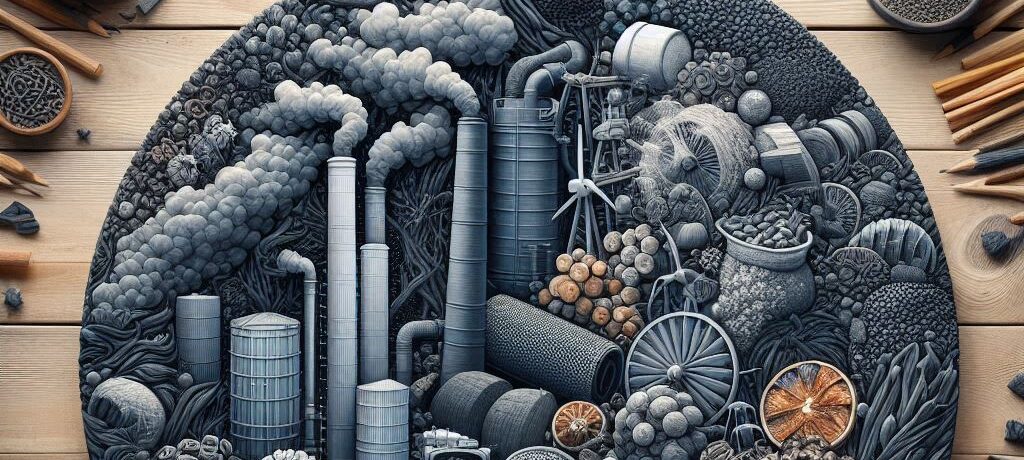

Continue readingCharcoal, Carbonization, and Torrefaction of biomass materials relate to their processing temperatures, chemical properties, and end uses:

1. Charcoal Production Process: Chemical Properties: Physical Properties: Applications: Environmental Impact: 2. Carbonization Overview: Process Details: Chemical Changes: Products: Applications: Environmental Benefits: 3. Torrefaction Process Characteristics: Chemical and Physical Changes: Process Steps: Product Characteristics: Applications: Advantages: Key Differences Summary: Feature Charcoal Carbonization Torrefaction Process Temperature 500–700°C 300–600°C 200–300°C Fixed Carbon High (70–90%) Medium to high […]

Continue readingGross Calorific Value (GCV) for torrefied and non-torrefied biomass pellets:

GCV of Biomass Materials (Torrefied vs. Non-Torrefied) to understand: 📞 Contact Us for Biomass Solutions📍 Servoday Plants & Equipments Limited📞 +91 9427210483 | +91 9427210484📧 sanjay@servoday.in🌐 www.PelletIndia.com👤 Contact Person: Sanjay Masuria📲 WhatsApp: +91 9427210483 PelletIndia.com – Concept to Commissioning Means, We Are With You! Since 1969 🚀🔥 Biomass Material GCV Non-Torrefied (kcal/kg) GCV Torrefied (kcal/kg) […]

Continue readingPelletIndia.com’s recent trial of wood biomass chip torrefaction continuous process:

PelletIndia.com‘s recent 1st trial of wood biomass chip torrefaction continuous process with biogas output provides some key insights. Here’s a breakdown of the key points based on our data: These details demonstrate a highly efficient, continuous torrefaction process with significant energy output and reduced operational costs.

Continue readingNapier Grass Vs Coal:

Napier Grass and Coal for use as energy sources, focusing on various factors like energy content, environmental impact, cost, and availability. I will also include a chart for visual reference. Comparison Table Factor Napier Grass Coal Energy Content 3,500-5,000* kcal/kg 5,000-6,500 kcal/kg Carbon Emissions Low (considered carbon-neutral) High (significant CO2 emissions) Ash Content Low (1-5%) […]

Continue reading